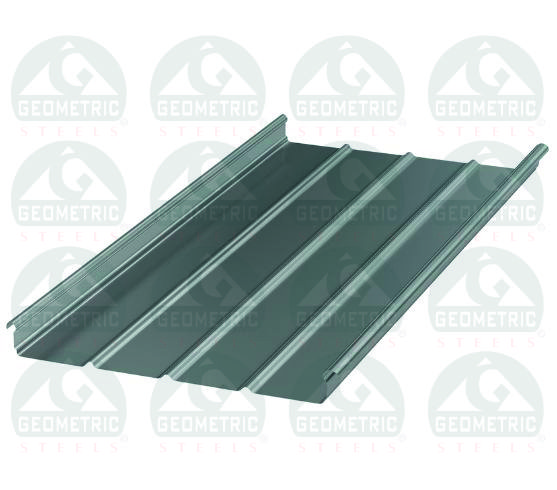

SteelzipTM

Standing seam that covers the entire building with panels joined together

with a double lock standing seam.

SteelzipTM

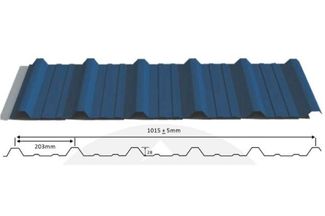

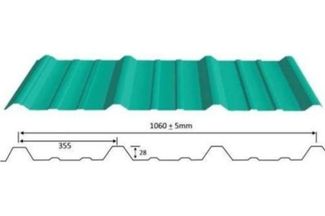

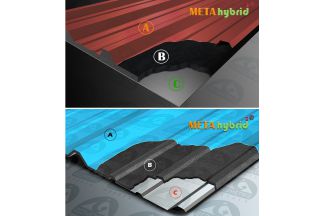

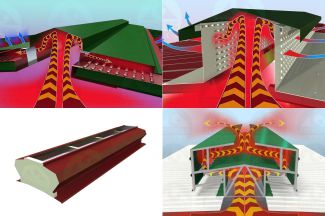

SteelzipTM standing seam metal roofing system is a steel membrane like structure covering entire building with panels joined together with a double lock standing seam and a unique clip is inserted into the seam on the construction site in a unique way that does not require via fasteners, holes or even through. They are then joined, and bonded using a portable electric seamer.

SteelzipTM The standing seam roofing system is connected to the structure with an innovative clip arrangement that does not require through panel fasteners, yet it is secured to stop wind from blowing away while allowing the roof sheet expand and contract with thermal contraction without compromising the structural quality.

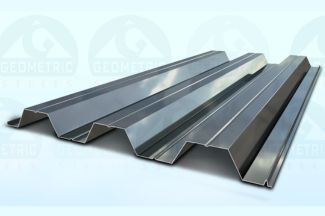

SteelzipTM standing seam roofing can be bent with a range of choices depending on the application. The shape can be concave waves, or convex with both curves incorporated into one sheet. Our modern tapering equipment can be used for rolling tapers in just one step from coils and also allows the fabrication of sheets with tapered edges at a comparable speed to parallel sheets.

SteelzipTM Advantages

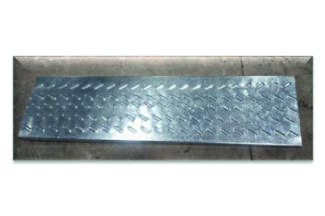

Fixing system that is self-supportingSingle length sheets of site roll, which are hidden roof fixing system

Breathing roof allows for expansion and contraction, as well as durability

With a 50mm seam height has been proven to be excellent for the flow of rainwater

Material and finishes: Colour Coated Galvalume, Aluminum & Colour Coated Aluminum meant for exterior applications. Durability and Corrosion Resistance

Installation- Forming the form on site according to dimensions and lengths that are required

Suitable for both warm and cold roof constructions – any shape including curved and/or tapered, and any pitch from 2° upwards.

The variety of shapes is available, which provides possibilities for stunning architectural designs.

The advantages of manufacturing on-site are visible when continuous lengths of sheets over 100 meters are utilised to cover large areas.

The system's lightweight and durability, as well as its quick construction time and versatility makes it suitable for both new construction and renovation projects.

It is also light weight, it weighs only 3-5 kg per square meter, it reduces the quantity of material utilised for supporting structures, which results in a reduction of resources.

Material: Aluminum, Color Coated Steel, Galvalume, or other metallic materials

Material Thickness : AAluminium 0.5 mm to 1.0mm, colour Coated Steel and Galvalume 0.5 mm to 0.8mm

Maximum Length : 100m per single panel

Minimum Radius : Concave Curve- aluminium 4m and Steel Curve 6m Convex Curve-aluminium 2m and Steel Curve 4m

colour Coating/Finish colour Coating/ Finish: All RAL-standard colours, with special colours available upon the request of the customer; minimum order requirements may be necessary.

Insulation Options : Glass wool / Rock Wool Blanket insulation.

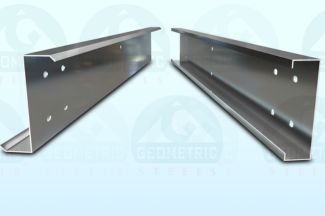

Accessories : We provide full range of customizable accessories such as clips, clamps, safety systems and equipment.

Usage : Airports, Exhibition halls, Sports Facilities, Industrial Buildings etc

SteelzipTM Gallery