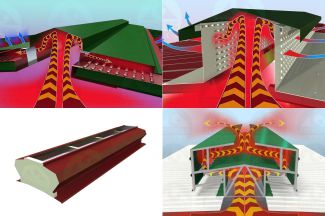

Skylight Polycarbonate Profile Sheets

Polycarbonate sheets are highly important in factory buildings due to their unique properties and advantages. Here are some reasons why:

Durability: Polycarbonate sheets are durable compared to FRP sheets and can withstand impacts, making them ideal for factory buildings that require sturdy material that can withstand harsh conditions..

Light Transmission: Polycarbonate sheets have excellent light transmission properties, which makes them ideal for factory buildings that require natural lighting. The sheets allow sunlight to pass through, reducing the need for artificial lighting and energy costs.

Thermal Insulation: Polycarbonate sheets have good thermal insulation properties, which help to regulate temperature and reduce energy costs. This makes them ideal for factory buildings that require temperature control.

UV Protection: Polycarbonate sheets are UV resistant, making them ideal for factory buildings that require protection from harmful UV rays.

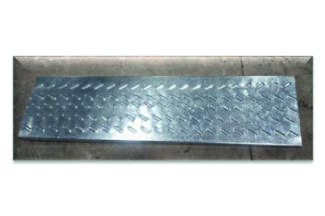

Easy to Install: Polycarbonate sheets are lightweight and easy to install, reducing installation time and costs.

Cost-effective: Polycarbonate sheets are cost-effective compared to traditional materials such as glass, making them a popular choice for factory building construction.

Polycarbonate roof profiles have gained popularity in recent years due to their durability, lightness, and ability to transmit light. However, as with any building material, certain precautions should be taken when using polycarbonate shingles:

Proper Installation: It is important to follow the manufacturer's installation instructions carefully to ensure that the polycarbonate is installed correctly. This includes making sure the sheets are properly supported, and tightly packed, and that there is enough overlap between the sheets to prevent water from seeping through.

UV Resistant: Over time Polycarbonate sheets are susceptible to UV damage which can cause them to yellow and become brittle. To avoid this, it is important to choose skin that has been treated with a UV coating.

Thermal Expansion: Polycarbonate sheets expand and contract as temperature changes. This puts pressure on the attachments and on the skin itself, which can cause cracks or damage. To avoid this, it is important to use the correct spacing between fasteners and to allow for thermal expansion when installing the panels.

Cleaning: Polycarbonate panels should be cleaned regularly to prevent the accumulation of dust and debris. However, it is important to avoid using abrasive cleaners or tools that can scratch the surface of the sheet.

Impact Resistance: Although Polycarbonate sheets are known for their durability, they can still be damaged by strong impacts. Care should be taken when handling and installing the panels and not exposing them to extreme weather conditions or heavy loads. Roof traffic should be completely avoided on polycarbonate sheets as this can result in a major accident

By following these precautions, you can ensure that your Polycarbonate profile sheets will provide long-lasting and reliable performance for your construction projects.

In conclusion, Polycarbonate sheets are highly important in factory buildings due to their durability, light transmission, thermal insulation, UV protection, ease of installation, and cost-effectiveness. They offer a range of benefits that make them an ideal choice for any factory building project

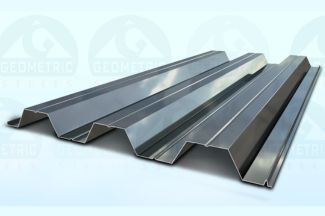

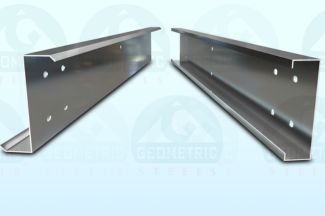

Geometric Steels is a professional manufacturer of polycarbonate sheets, we are committed to providing high-quality Polycarbonate sheets that meet the highest industry standards as per any profile design required. Polycarbonate sheets are highly important in factory buildings due to their durability, light transmission, UV protection, ease of installation, and cost-effectiveness. Also, it is a long-lasting and reliable protection for employees and equipment.

Contact us today to learn more about Polycarbonate sheets.